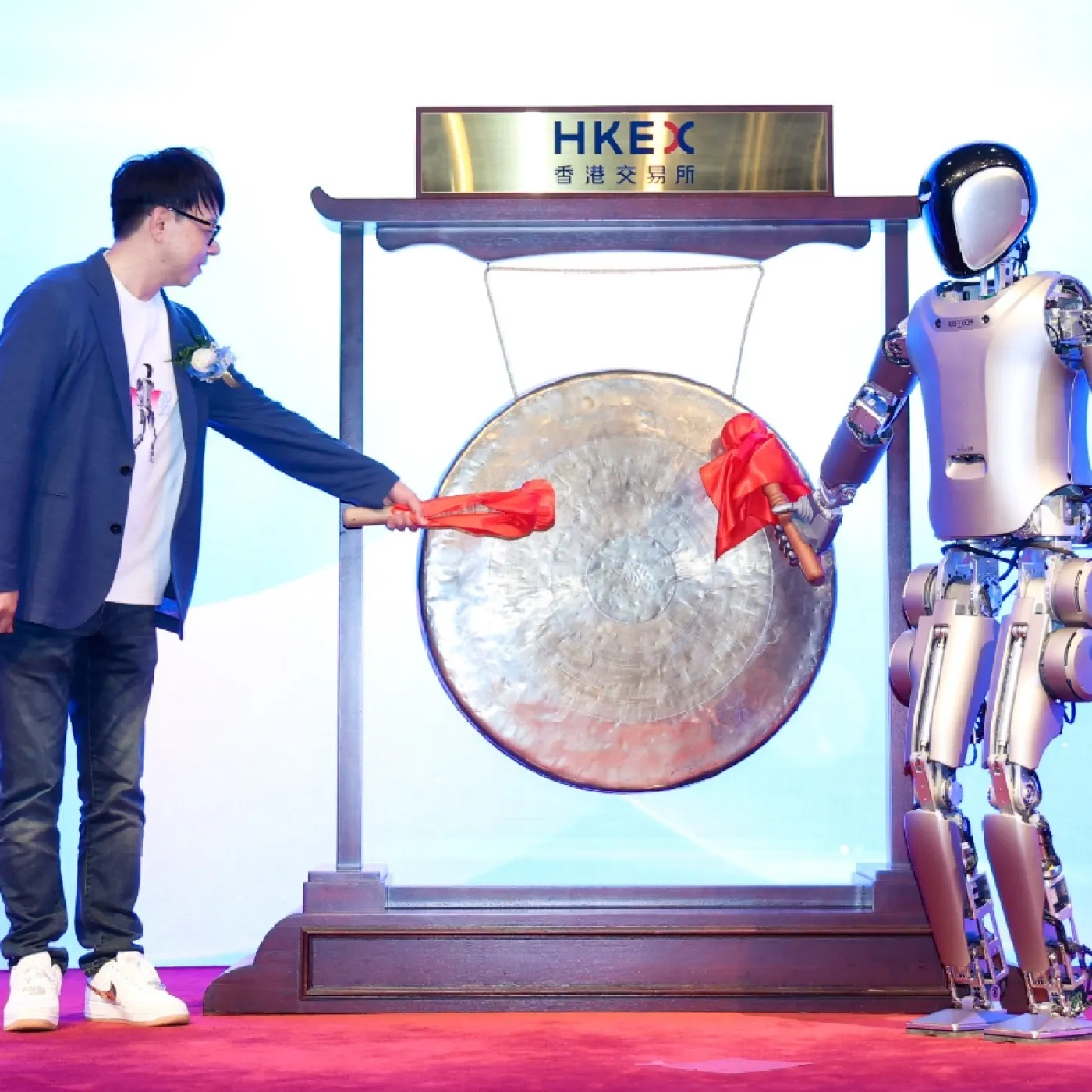

China’s manufacturing sector is set to witness a transformative shift as humanoid robots prepare to take on the assembly of iPhones. This innovation, spearheaded by leading robotics firms, represents a significant step forward in automation, addressing labor shortages while enhancing precision and efficiency in production.

The Role of Humanoid Robots

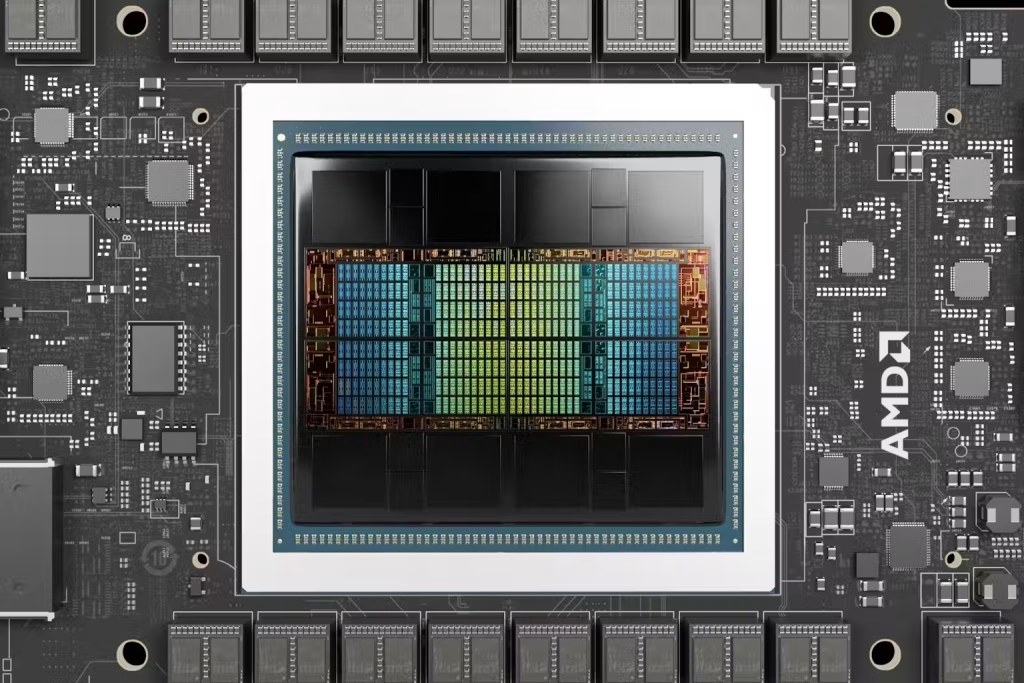

Humanoid robots are being developed to perform intricate assembly tasks traditionally handled by human workers. These robots are equipped with advanced AI, machine learning, and dexterous robotic arms, enabling them to handle the delicate components of modern smartphones.

- Precision Engineering:

- Robots are designed to perform high-precision tasks such as assembling circuit boards, connecting micro-components, and applying adhesives with consistent accuracy.

- Increased Productivity:

- Unlike human workers, robots can operate 24/7 without fatigue, significantly boosting production output.

Driving Factors Behind the Transition

Several factors have motivated the adoption of humanoid robots in iPhone assembly lines:

- Labor Shortages:

- China’s manufacturing sector faces challenges due to an aging workforce and a declining pool of young workers willing to take up repetitive assembly jobs.

- Cost Efficiency:

- While initial investment in robotics is high, the long-term savings from reduced labor costs and enhanced productivity make it an attractive proposition.

- Technological Advancements:

- Breakthroughs in AI, robotics, and sensor technology have made humanoid robots more capable and affordable for industrial use.

Impact on the Manufacturing Industry

The introduction of humanoid robots is poised to redefine the manufacturing landscape in several ways:

- Enhanced Quality Control:

- Robots can consistently meet exacting quality standards, reducing errors and defects in the assembly process.

- Supply Chain Resilience:

- Automation mitigates risks associated with labor disruptions, such as strikes or pandemics, ensuring uninterrupted production.

- Shift in Workforce Dynamics:

- While robots replace manual assembly roles, they create demand for highly skilled workers to manage, program, and maintain the robotic systems.

Challenges and Considerations

Despite its promise, the adoption of humanoid robots also presents challenges:

- High Initial Costs:

- The development, installation, and integration of humanoid robots require substantial capital investment.

- Ethical and Social Concerns:

- Replacing human workers with robots raises concerns about job displacement and the socio-economic impact on local communities.

- Technical Limitations:

- While advanced, robots may still struggle with highly complex or non-standardized tasks.

Future Outlook

The deployment of humanoid robots in iPhone assembly lines is a harbinger of a broader trend in manufacturing automation. As technology evolves, robots are likely to take on more sophisticated roles, further enhancing efficiency and redefining industrial processes.

- Global Implications:

- This development could set a precedent for manufacturers worldwide, accelerating the adoption of robotics in various industries.

- Sustainability Goals:

- By optimizing production processes, robots can reduce waste and energy consumption, contributing to more sustainable manufacturing practices.

Conclusion

The integration of humanoid robots into iPhone assembly lines marks a pivotal moment in the evolution of manufacturing. Balancing the benefits of automation with ethical and social considerations will be key to ensuring a harmonious transition to this new era of industrial innovation.

For more information, visit Interesting Engineering.