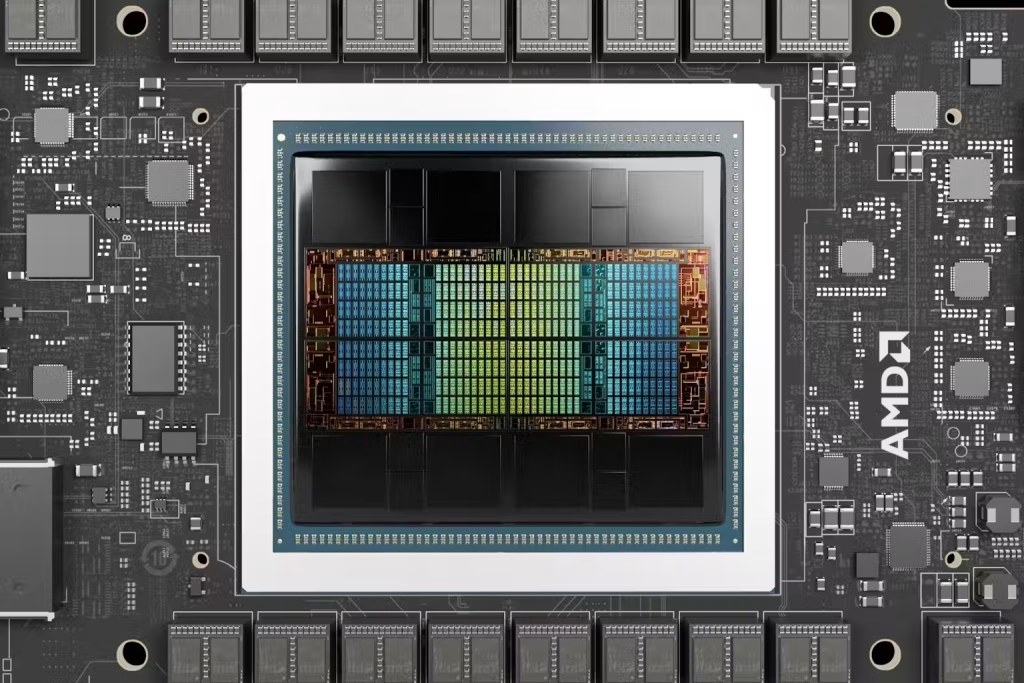

Apple is on the cusp of a significant milestone in its supply chain strategy: sourcing semiconductor chips made in the United States. Taiwan Semiconductor Manufacturing Company (TSMC), the world’s leading chip producer, is nearing the final stages of quality verification for chips produced at its new Arizona facility. This development marks a pivotal step in reshaping the global semiconductor supply chain.

A Strategic Shift Toward Domestic Manufacturing

The Arizona facility represents TSMC’s first major manufacturing site in the U.S. and is part of a broader effort to diversify production amid increasing geopolitical tensions. Apple, one of TSMC’s largest customers, has been a driving force behind the facility’s establishment. By securing domestically produced chips, Apple aims to enhance supply chain resilience and align with the U.S. government’s push for technological self-sufficiency.

Facility Overview and Progress

The Arizona fab, a multi-billion-dollar investment, is designed to produce advanced semiconductors using TSMC’s cutting-edge 4nm process. Once fully operational, the facility will bolster U.S. capabilities in producing high-performance chips for smartphones, computers, and other advanced electronics.

- Quality Verification:

- TSMC is conducting rigorous testing to ensure that chips meet Apple’s stringent performance and reliability standards. This phase is critical to securing Apple’s trust and scaling production.

- Timeline:

- Initial production batches are expected to be delivered in early 2025, with the facility ramping up to full capacity shortly thereafter.

Implications for Apple and the Semiconductor Industry

Apple’s move to source chips from the U.S. aligns with its sustainability and localization goals. It also reflects a broader industry trend as manufacturers seek to mitigate risks associated with reliance on overseas production.

- Enhanced Supply Chain Security:

- The Arizona fab reduces dependence on chips from Asia, particularly Taiwan, which has been a focal point of geopolitical tensions.

- Economic and Political Impact:

- The project underscores the effectiveness of U.S. incentives, such as the CHIPS Act, in attracting high-tech manufacturing. It is expected to create thousands of high-skilled jobs and stimulate economic growth in the region.

- Potential Challenges:

- Despite its promise, the project faces hurdles, including scaling production to meet global demand and maintaining cost competitiveness with TSMC’s Asian facilities.

A Broader Trend of Localization

TSMC’s Arizona facility is part of a growing trend among tech giants to localize critical manufacturing. With increasing pressure from governments worldwide to ensure supply chain sovereignty, similar projects are underway in Europe, Japan, and other regions. Apple’s commitment to sourcing chips from the U.S. sets a precedent for other companies to follow.

Conclusion

The completion of TSMC’s Arizona fab marks a significant advancement in the U.S. semiconductor industry and Apple’s supply chain strategy. While challenges remain, the successful production of chips in America could reshape the global semiconductor landscape, fostering innovation and stability in a rapidly evolving market.

For more information, visit TSMC’s Arizona Fab.